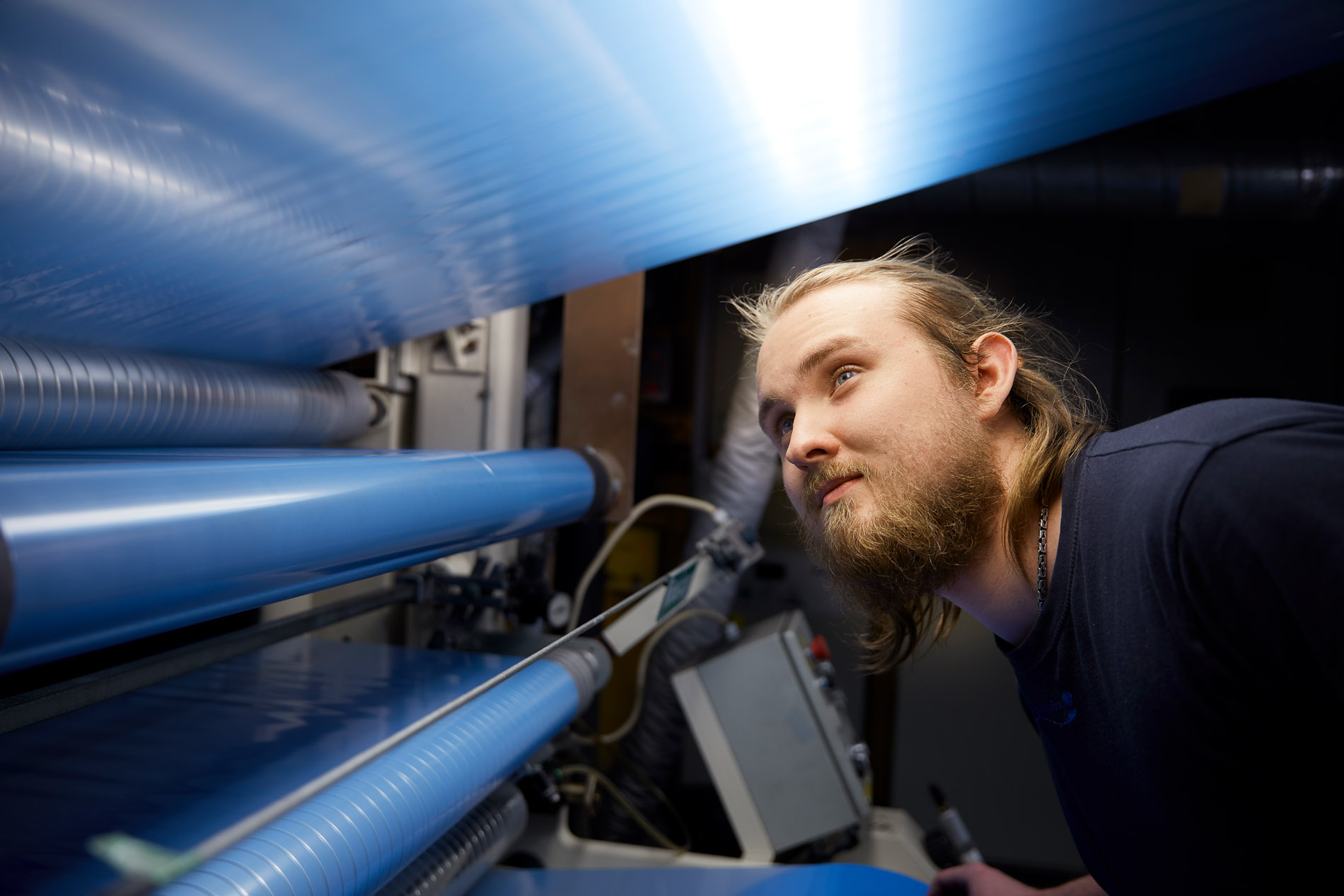

Lamination & Coating

Thin flexible laminates

The lamination process combines two or more materials to each other with adhesive in order to obtain new or improved properties. Coating is a process of applying a thin and uniform layer on the film/foil in order to add specific characteristics to its surface.

Skultuna Induflex supplies a full range of material combinations for production of thin, flexible materials. We combine and coat materials such as plastic films, metal foils, paper and cardboard, to create an almost infinite number of tailor-made flexible laminates that meet our customers’ specific needs. These feature properties that make it possible to solve problems in new ways, whether it’s laminates for shielding, barrier, conduction, flexible circuits, reflection, appearance, or other purposes.

Laminates are manufactured from roll-to-roll:

• Metal foils 6–200 µm

• Polymer films 4–300 µm

• Papers and cardboards 40-500 g/m²

• Other thin materials on reels

In our standard product range, we manufacture two-layer laminates but we are also able to laminate multilayer laminates up to 5 layers in widths of maximum 1600 mm, providing you with flexible production possibilities. Laminates and raw materials can be enhanced by the addition of functional and decorative coatings and primers, including lubrication, corrosion protection and fire resistance.

for more information about our capabilities